Metal Data Matrix Code Bars-Rugged Solution for Your Positioning System

Whether in combination with Automated Guided Vehicles (AGVs), skid units, or monorail conveyor systems in the automotive industry, Data Matrix code tapes from Pepperl+Fuchs ensure the highest level of precision and maximum reliability for positioning and track guidance. The polyester laminate code tapes previously used for this purpose are primarily suited for applications that are subject to moderate levels of stress. That is why Pepperl+Fuchs has developed a new model for use in harsh industrial environments: metal Data Matrix code bars made of printed aluminum. In this blog article, you will learn how these code bars can make your PGV or PXV positioning solution more durable and rugged.

Your Benefits at a Glance

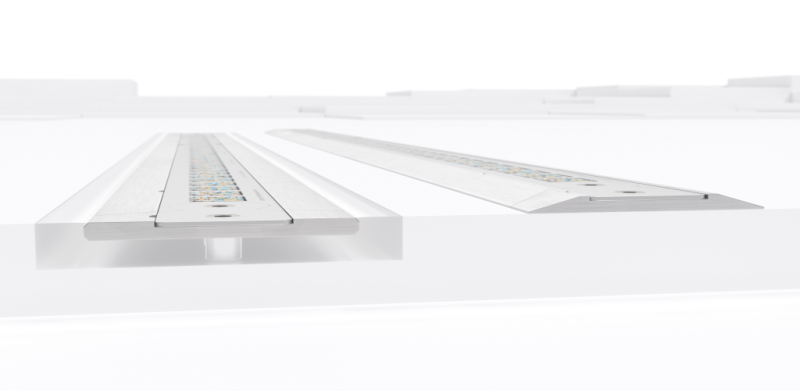

When using the PXV and PGV Data Matrix positioning systems, Data Matrix code bars are fixed onto or embedded into the floor and read by a read head located on the moving part of the system. While the camera-based track guidance solutions of the PGV series are ideal for Automated Guided Vehicles (AGVs), the camera-based linear positioning systems of the PXV series are suitable for linear applications such as the positioning of skid unit systems and monorail conveyor systems.

Compared to conventional code tapes made of polyester laminate, the key advantage of the new metal Data Matrix code bars is that they are made of printed aluminum. This means they are significantly less sensitive to mechanical stress and impress with their extremely high level of resistance.

How to Install the Code Bars

Three different options are available for the installation of the metal Data Matrix code bars:

- Directly bonding the code bars to the ground

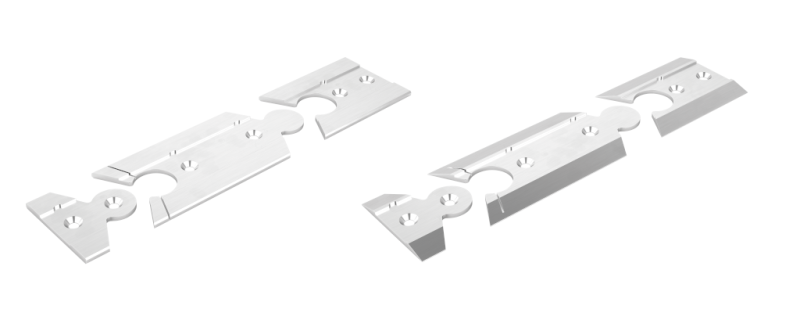

- Mounting in drive-over profile rails

- Mounting in countersunk profile rails

While directly bonding the code bars to the ground considerably simplifies the installation process, using drive-over or countersunk profile rails provides additional mechanical protection. All three options have an adhesive strip attached to the bottom of the code bars to facilitate installation.

The Most Important Product Details

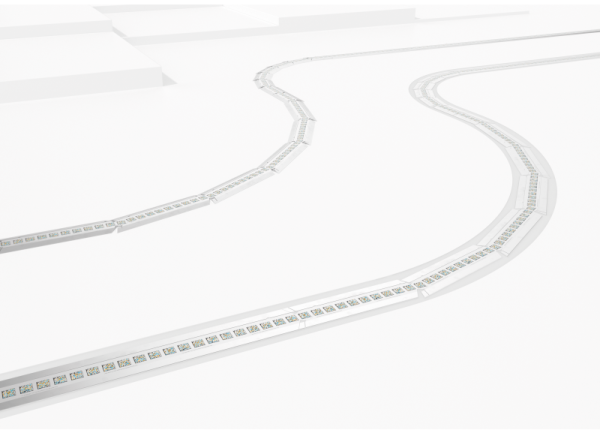

Whether you want to master long distances or tight curves, the positioning solutions from Pepperl+Fuchs can be adapted to your individual requirements. For this purpose, the metal Data Matrix code bars and the associated drive-over and countersunk profile rails are available in various lengths:

- The 500 mm module is suitable for long, straight sections

- The 200 mm module is recommended for curves and dynamic areas

- If the 200 mm modules are not dynamic enough for your application, 100 mm modules can be used

Of course, start and end profile rails are also available. All components are designed with positive connections and are compatible with each other, so you can seamlessly transition between areas with different installation methods.

Complete System for Positioning and Track Guidance

Pepperl+Fuchs offers a complete portfolio for high-precision positioning and track guidance for the PXV and PGV series systems. The new metal Data Matrix code bars are the ideal solution for minimizing maintenance in harsh industrial environments. Our experts will be happy to assist you in choosing and configuring the optimal system for your positioning application.

Via Pepperl & Fuchs