How to Assemble the VOS 2-D Universal Vision Sensor for Your Application

High-resolution industrial vision systems are used, among other things, for the detection and comparison of features, the positioning and guidance of objects, optical measurement, or code and text recognition (OCR) in various industrial applications. They ensure fast and precise inspection and quality control of objects or components. These applications usually require a complex vision system. With the VOS 2-D universal vision sensors, Pepperl+Fuchs offers a vision tool set consisting of only one vision sensor with flexibly combinable hardware components, tailored to your complex vision tasks.

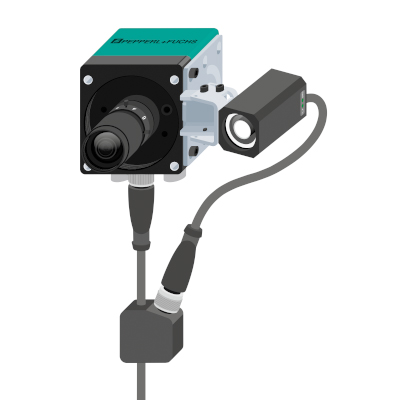

The VOS 2-D universal vision sensor portfolio offers high scalability on the hardware side, from simple vision applications to more demanding tasks. In this blog article, you will get an overview of the VOS hardware components as well as the criteria for the optimal mix so that you can tailor your vision sensor exactly to your application. Pepperl+Fuchs offers compact camera models with integrated lighting and C-mount variants with external lighting. Put together the right 2-D vision sensor for your application from the portfolio of C-mount variant, lens, system lighting, and protective cover. Continue reading to learn how to assemble the VOS 2-D universal vision sensor.

VOS 2-D Universal Vision Sensors: Overview and Selection Criteria

Compact Cameras

The VOS vision sensor series offers various devices for a wide range of requirements in industrial vision applications. In the compact cameras of the VOS1000 and VOS2000 series, lens and system lighting are already integrated in the sensor. Due to the different resolutions from 640 × 480 pixel (VOS1000) up to 1280 × 960 pixel (VOS2000), the sensors are suitable for standard tasks as well as for more demanding, high-resolution measurement tasks with incident light in the 2-D vision range. Here, the adjustable camera focus can be mechanically set to the required measuring range on the outer ring. This allows you to select the mounting position with a distance to the object between 100 mm and 1000 mm.

C-Mount Variants for Challenging Lighting Scenarios

The 2-D vision sensors of the VOS2000 and VOS5000 series are also available as C-mount variants for demanding applications. The C-mount variants have a pulse output with which they can control external industrial lighting. In addition, they can be combined with the appropriate lenses to suit your application. This makes the VOS C-mount vision sensors suitable not only for standard applications with incident light but also for measurement tasks with challenging lighting scenarios, larger distances and even higher accuracy.

For Even More Precise Recordings: Special Accessories for C-Mount Cameras VOS2000 and VOS5000

Lenses for Different Distances and Focal Lengths

For the C-mount cameras, you can also choose from precision lenses with different focal lengths ranging from 6 mm for short distances with a large field of view to 50 mm for longer distances and a small field of view. Focus and aperture can be adjusted manually to achieve the optimum field of view at any distance and thus the greatest image sharpness. The 2/3″ standard lenses are suitable for the VOS2000 series sensors, while the high-resolution 1″ lenses are tailored to the VOS5000 series.

System Lighting

In optical testing, sunlight, incident light from the side, or changing ambient light play a particularly important role. A very high light intensity with power LEDs and flash operation can counteract this so that ambient light-stable applications can be realized. Various designs and different opening angles allow optimal lighting of the field of view while the light output can be regulated via the integrated flash controller depending on the operating distance. The maximum light output allows ambient light-safe detection over long distances to enable reliable detection of objects and codes during rapid movement—even with very short flash times. Depending on the application, the lighting can be aligned in such a way that the “differences” on the object are optimally visible and can be highlighted in the inspection image and evaluated by the vision tools.

System lighting for the C-mount versions of VOS2000 and VOS5000 series 2-D vision sensors from Pepperl+Fuchs

Depending on the orientation of the lighting to the camera, there is either a so-called bright field or dark field lighting. Here, the camera detects the shape of the object in the projection plane and the light reflected from the object in the reflection plane. The lighting is selected based on the field of view width at a required distance. In each system lighting, optics are installed for various opening angles of the light. The lightings have different mounting adapters for the vision sensors VOS2000 and VOS5000.

Protective Cover

The protective cover is screwed onto the camera over the lens to protect it from the effects of dust or moisture. This ensures degree of protection (IP65). The protective cover is tailored to the respective C-mount camera lenses.

The protective cover is screwed onto the camera over the lens to protect it from the effects of dust or moisture. This ensures degree of protection (IP65). The protective cover is tailored to the respective C-mount camera lenses.

Connection Technology

The T-cable set simplifies connection and mounting of the VOS vision sensors. The system lighting and the camera are supplied with power at the same time, so that 24 V are only connected once. At the same time, the camera’s pulse output is connected within the cable to the trigger input of the system lighting. With that, the light intensity and the timing of the light flash can be controlled in the camera’s user interface.