Yokogawa IA2IA

In a business environment ruled by high volatility, uncertainty, complexity, and ambiguity (VUCA), manufacturers in process industries are increasingly embracing emerging digital technologies to transform operations, control costs, reduce downtime, and improve profitability.

To address these challenges, companies in the process industries have set smart manufacturing goals in applying digital transformation technology to manufacturing operations. Yokogawa believes, for many end users, autonomous operations is the destination to achieve their smart manufacturing goals.

IA2IA – Industrial Automation to Industrial Autonomy

Currently, all companies are at some stage of automated operations as a starting point.

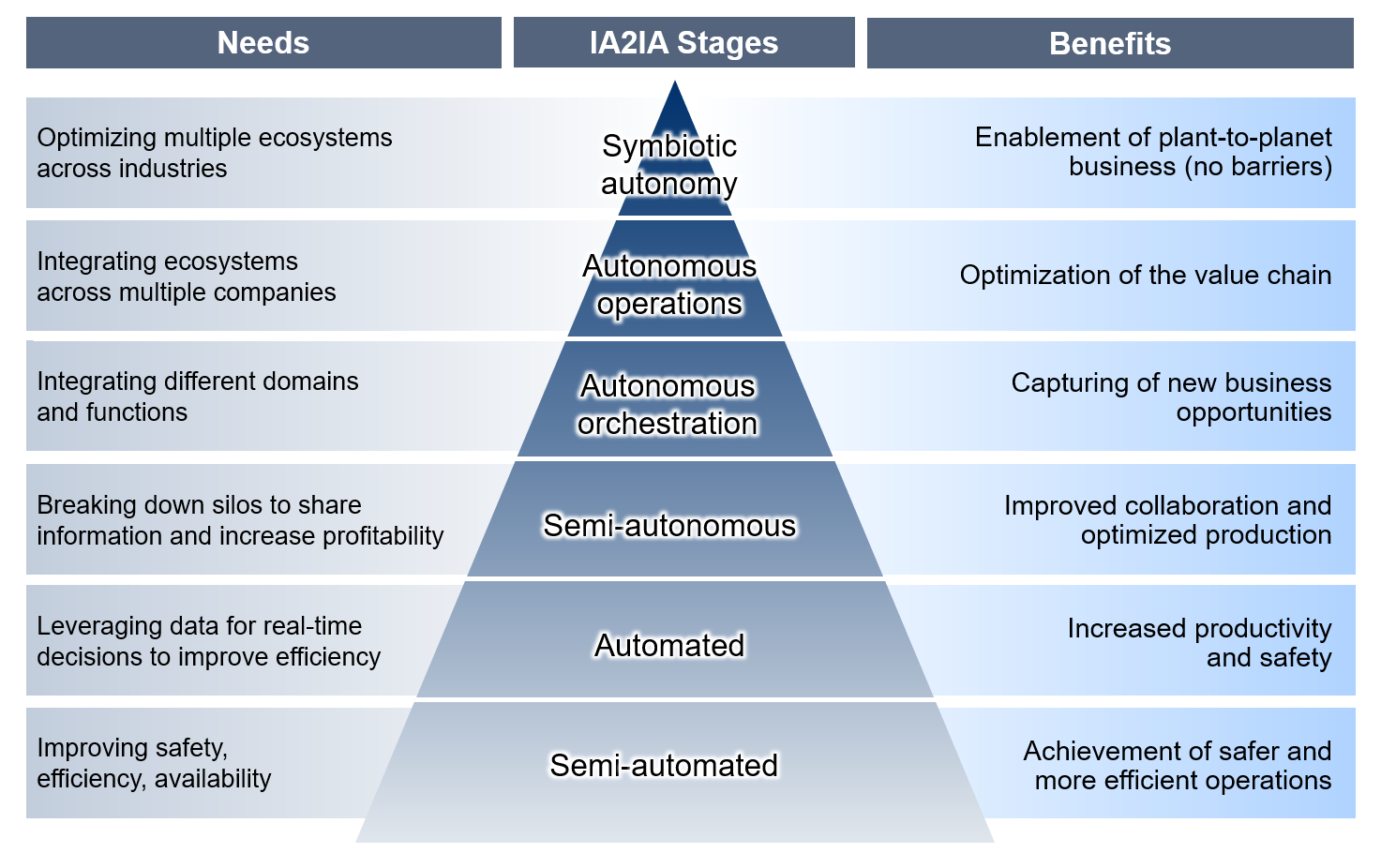

IA2IA is what Yokogawa foresees as the transition from Industrial Automation to Industrial Autonomy.

What is “Industrial Autonomy”?

Autonomy means to be independent or to be able to control or govern oneself. It is different from automation, which performs a sequence of highly structured pre-programmed tasks requiring human oversight and intervention. Industrial Autonomy is where plant assets and operations have learning and adaptive capabilities that allow responses with minimal human interaction, empowering operators to perform higher-level optimization tasks.

What is “Autonomous Operations”?

Autonomous operations is the final stage of industrial autonomy, represents an ideal state where operations function with complete autonomy throughout a value chain. Autonomous operations can be defined as assets and operations that have human like learning and adaptive capabilities that allow them to respond without operator interaction to situations within a secure bounded domain that are not pre-programmed or anticipated in the design and is responsible for all safety-critical functions. In a fully autonomous operation (no human intervention required), the cognitive system performs all aspects of the operation.

Levels of Autonomy – a Transition to be Taken in Steps

Autonomy will expand to multiple functional domains including process control and operations, planning & scheduling, supply chain management, field operations, maintenance, and engineering. To jump directly to autonomous operations is very difficult to achieve. Therefore, Yokogawa has developed a maturity model to establish where companies are today and where they need to be in the future.

Level 0-1 MANUAL/SEMI-AUTOMATED

A facility is minimally instrumented and automated. Many operations are performed manually with paper-based instructions and record keeping. The automation system conducts some of the production processes to eliminate error prone operations and improve productivity.

Level 2 AUTOMATED

Humans are responsible for safe operations, assisted by traditional automation systems. The automation system conducts majority of production processes and aids in workflow and maintenance tasks but requires human oversight and intervention to properly deal with anything that’s outside of normal operations.

Level 3 SEMI-AUTONOMOUS

It is characterized by a mixture of autonomous components and automated assets with human orchestration. An autonomous component is different from automation due to its learning, adaptive, and self-optimization capabilities to situations that are not pre-programmed. Companies at this level deploy a range of selective autonomous components or applications orchestrated by humans.

Level 4 AUTONOMOUS ORCHESTRATION

Most assets operate autonomously and are synchronized to optimize production, safety, and maintenance under certain circumstances or conditions. It brings together autonomous components with appropriate functionality to perform as a system. However, there is still a need for humans to perform many tasks as not all disciplines are integrated at this level. In addition, if the specific circumstances are not met,then the operators must take control of the operation.

Level 5 AUTONOMOUS OPERATIONS

A highly idealized state where facilities operate autonomously and are integrated with multiple disciplines that also operate autonomously and extend to supply chain partners. Operations are completely autonomous and require no human interaction at all.

Beyond Autonomous Operations

Yokogawa envisions an additional transcendent step of “Symbiotic Autonomy” on top of operations, which focuses on more collaboration across industries as well as eco-systems such as the energy sector.

In Symbiotic Autonomy, the autonomous operations of multi-collaborating ecosystems are brought together to look beyond an individual plant and achieve autonomous interaction of data and resources between separate plants. In a world that expects corporations to consider their operations from the point of view of world sustainability, this approach can deliver multi-win outcomes for a broader range of stakeholders.

Yokogawa is taking a leading role to make symbiotic autonomy a reality across the world.

Information Digital Transformation Leaders Need to Move to Autonomy

Digital transformation leaders have the challenging and complex task of transforming operations, getting people, processes, and technology to work together, and leading their organizations on the journey to a successful digital transformation that will make operations sustainable, smart, and autonomous. To have a better understanding of IA2IA and succeed in this journey, read our IA2IA eBook, A Digital Transformation Leaders’ Guide to Industrial Autonomy . In this eBook, you will learn more about IA2IA and how Yokogawa can help you with your journey towards autonomous operations.

Via Yokogawa