Reliable and accurate sampling system for natural gas applications

This case study demonstrates a reliable sampling solution currently used by plant operators. It helps plant operators to obtain representative samples.

Customer Challenge

Sampling system is difficult to install and maintain. Furthermore, it does not provide reliable and accurate analysis results.

Running an efficient operation requires reliable, real-time data. That data can be obtained through representative sampling.

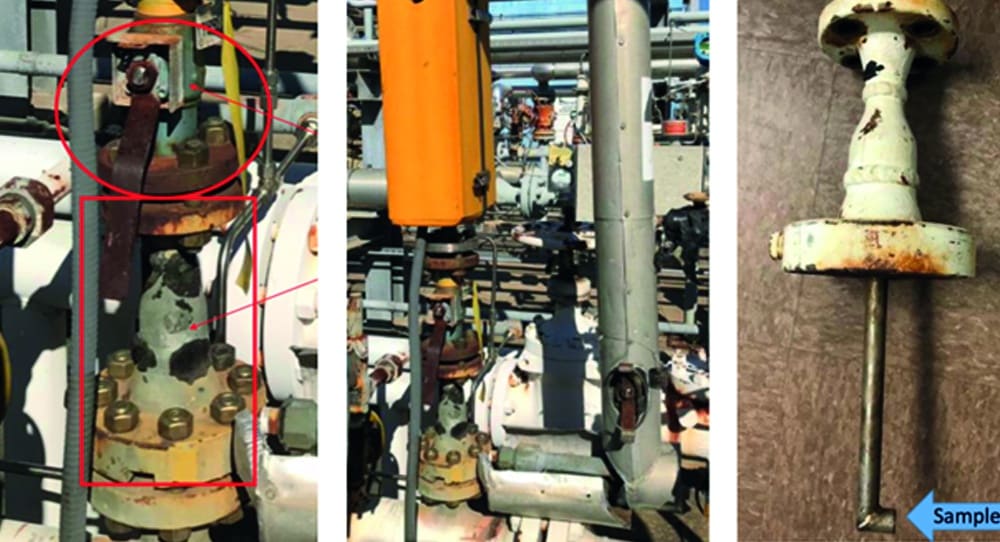

The typical sampling arrangement, in a natural gas plant, consists of a flanged end probe extractor, a flanged ball valve, and the measuring instrument. This setup presents several challenges to the plant operators:

- Traditional setup is very bulky. It requires several man hours and accessories to assemble.

- There are multiple connection points between different components of the traditional setup. These reduce the reliability of the system due to a large number of possible leakage paths.

- In order to obtain a representative sample, gas must be drawn from a well-mixed point within the pipeline. The gas near the sidewalls of the pipeline may contain contaminants that could affect a correct reading.

- The gas that flows into the sampling system must flow back to the main pipeline, without on-site personnel coming into contact with the media. The sampling therefore requires an isolated looping design. Such a design can further increase the number of components and possible leak paths.

- Servicing or replacement of a component in the sampling system requires production to be stopped. Only afterwards can the system be disassembled.

The Solution

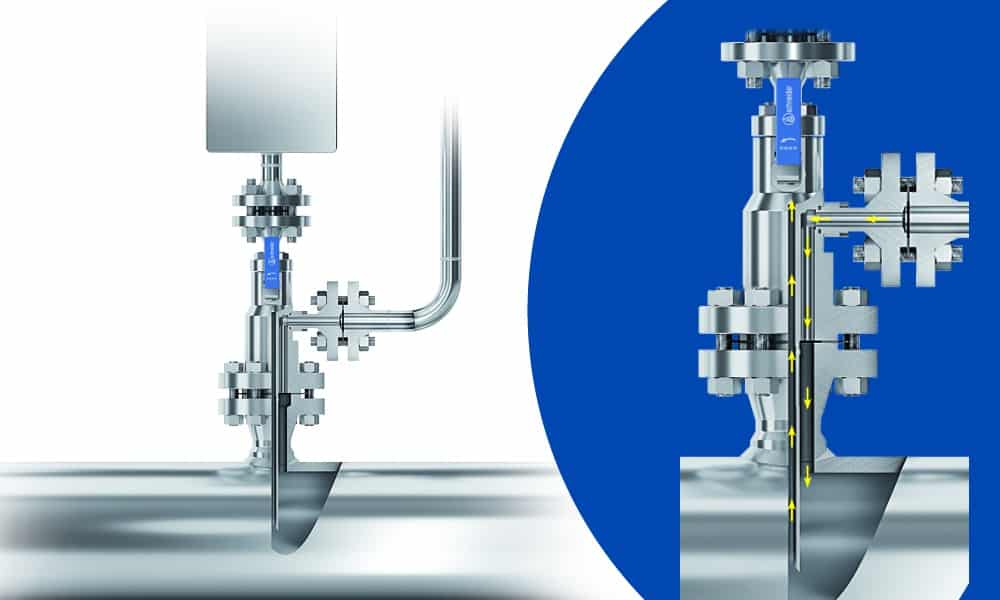

We customized the sampling valve to customer needs. Our sampling valve helps the plant operators obtain representative samples safely & reliably. Furthermore, it reduces installation and maintenance costs.

Requirement Description

AS-Schneider offers sampling and injection valves. These valves help meet some of the challenges mentioned above such as a compact design and fewer potential leakage paths.

Companies in the natural gas supply chain that were already using these products approached AS-Schneider for a customized product that would completely meet their specific needs.

In response to customers demand, AS-Schneider went back to the drawing board to address these issues. The sampling valve design was used as a starting point; modifications were incorporated in the base design to resolve the issues faced by their clients.

Target Specifications

- The main objective of the redesign was to make the valve suitable for measuring devices that require a looping flow.

- Another important design target was to allow the product to be retrieved from a well-mixed point within the pipeline. Besides, it should not be placed on the sidewalls.

- Furthermore, it was important to ensure that the modifications allowed for maintenance and service of the sampling setup without the need to stop production.